Computerized embroidery work Process, Benefits & Uses this title tell us how garments are designed, customized, and stitched with precision in modern fashion.

You have a vision —Custom embroidery service , a logo stitched onto a corporate jacket, or a trending geometric pattern across your kurta.

But turning that vision into flawless stitchwork on real fabric? That is exactly where computerized embroidery work steps in.

This guide explains computerized embroidery work in detail, covering its process, benefits, and real-world uses.

It is no longer a luxury reserved for fashion houses. In 2026, anyone who wants a custom-designed, professionally embroidered garment can get it — quickly, precisely, and affordably.

This guide walks you through exactly how the process works, what makes it special, and how you can use it to transform your wardrobe or brand.

1.What is Computerised Embroidery Work?

Computerised embroidery work is the process of using software-controlled machines to stitch intricate designs, patterns, and motifs directly onto fabric — with a level of precision that is nearly impossible to replicate by hand at scale. Unlike traditional hand embroidery, where every stitch depends on an artisan’s manual effort, computerized embroidery converts a digital design file into a set of precise stitch instructions that the machine executes automatically.

Think of it this way: if hand embroidery is painting on canvas, computerized embroidery is high-resolution digital printing — but with thread instead of ink. The result is crisp lines, consistent color density, and designs that look identical whether you produce one piece or five hundred.

Whether you want a single personalized piece or a bulk order for an event, computerized embroidery gives you both the quality of handcrafted work and the reliability of industrial-grade machinery. It is the backbone of modern custom embroidery services across India.

This technology is behind the crisp logos on corporate wear, the elaborate Zari patterns on bridal lehengas, the trending designs on streetwear, and the personalized monograms on gifts. It is fast, scalable, and — when done right — indistinguishable from the finest handwork.

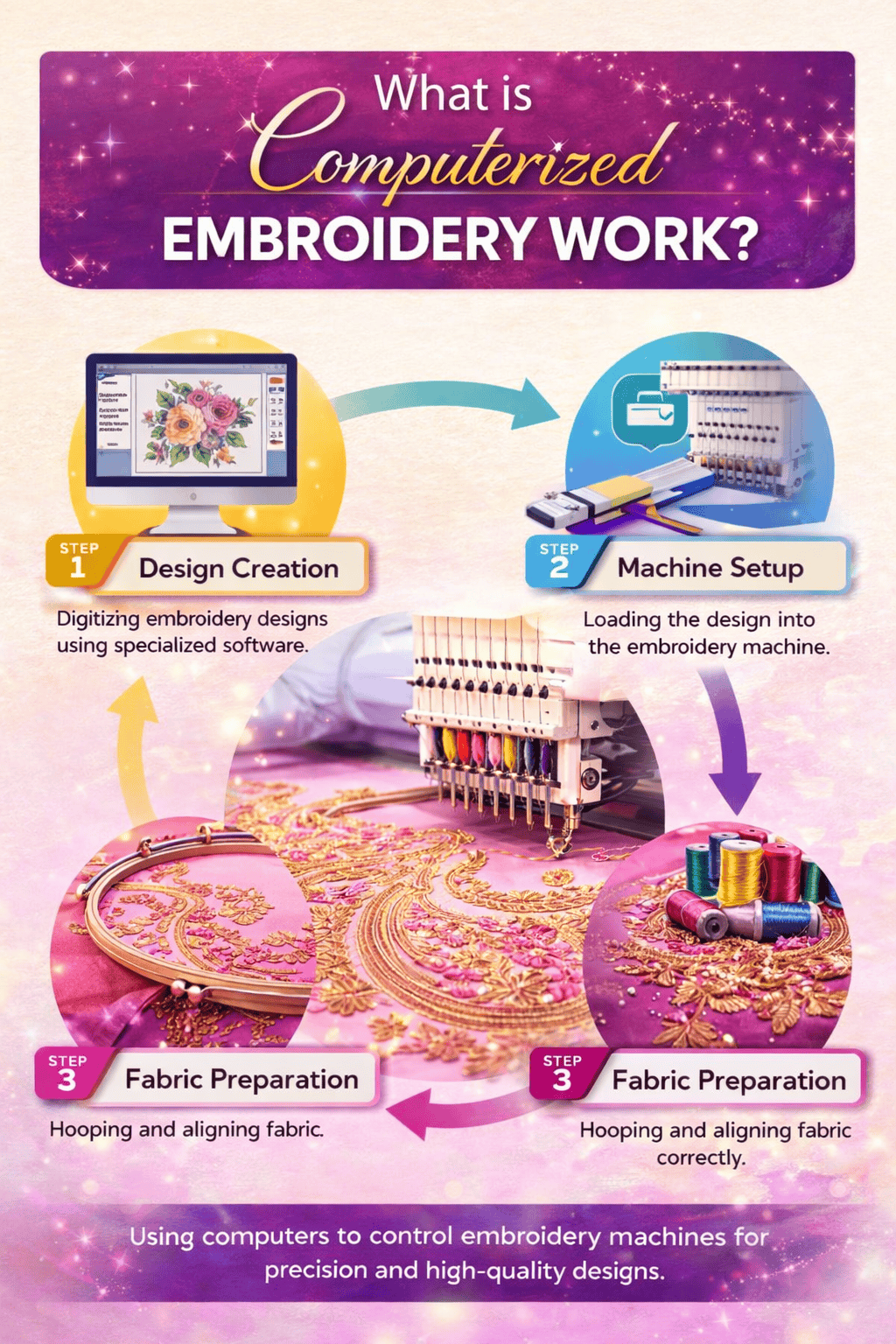

2.How Does Computerized Embroidery Work?

The magic behind computerized embroidery happens across a clear, repeatable process. Here is exactly what happens from the moment you have a design idea to the moment you hold the finished garment in your hands.

-

Design Creation or Selection

You either upload your own artwork, choose from a library of ready-made machine embroidery designs, or work with a designer to create something entirely original — a logo, a floral motif, a Zari-inspired border, or a trending pattern.

-

Digitizing — The Core Step

This is where your image or vector file gets converted into a .dst, .pes, or .jef stitch file. Digitizing software (or a skilled digitizer) maps out exactly where each stitch goes, in what direction, and with which thread color. This step determines the final quality of your embroidery — it is the difference between a sharp, clean result and a messy one.

-

Thread Selection & Color Matching

Thread color is matched to your design using standardized thread brand charts (like Madeira, Robison-Anton, or Poly-King). For Zari embroidery, metallic threads — gold, silver, or copper-coated — are selected to achieve that signature luminous shimmer.

-

Fabric Hooping

Your garment or fabric is placed into a hoop — a frame that holds the material taut and flat against the machine’s needle plate. Proper hooping is critical: even slight puckering or slippage will distort the final design.

-

Machine Stitching

The computerized embroidery work machine reads the stitch file and begins stitching. Multi-needle machines can hold up to 10–12 thread colors simultaneously, meaning complex designs complete without manual thread changes. A single machine can produce 700–1,000 stitches per minute.

-

Quality Check & Finishing

Once stitching is complete, the embroidery is inspected for stitch density, color accuracy, and edge neatness. Any excess stabilizer or backing is trimmed, and the garment is steamed or pressed to a finished look.

Zari Zaika’s Approach

At Zari Zaika, every order goes through a dedicated review after digitizing — before a single stitch is made. This ensures your design translates perfectly from screen to fabric, with zero compromise on the details that matter most.

Watch how computerized embroidery machines work step by step

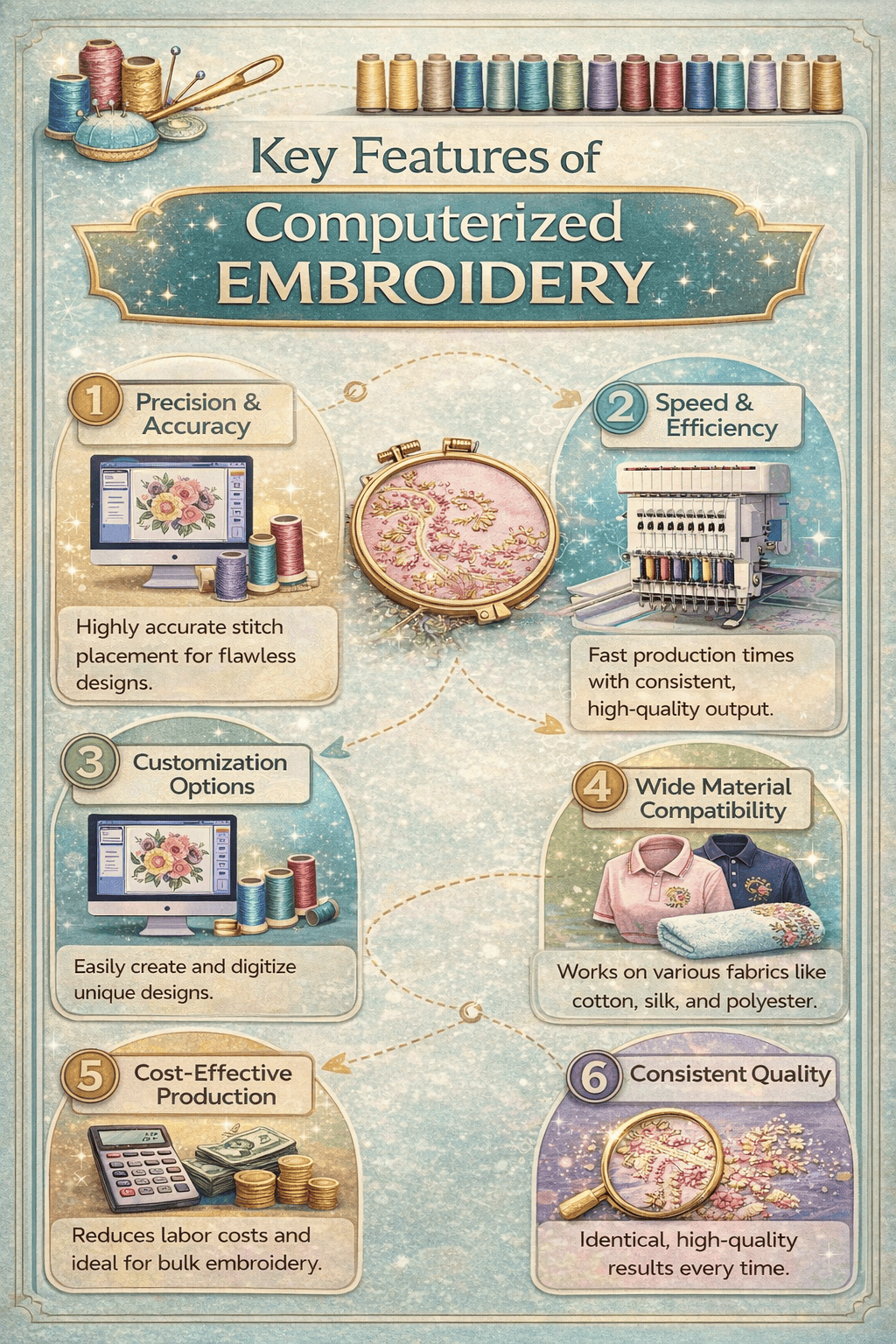

3.Key Features of Computerized Embroidery

What separates computerized embroidery from other decoration methods is a combination of technical capabilities that no other process can fully match. Here are the features that make it the go-to choice for both individuals and brands.

🎯Stitch Precision

Machines execute every stitch at the exact coordinates programmed — no human tremor, no inconsistency.

🔁Perfect Repeatability

Every unit in a batch looks identical. Perfect for uniforms, event wear, or branded merchandise.

🎨Unlimited Color Options

Choose from thousands of thread colors — including metallics like gold Zari and silver — to match any vision.

⚡Speed & Efficiency

A design that would take a hand-embroiderer days can be completed by machine in hours or less.

📐Design Scalability

Resize, mirror, or duplicate a design digitally before stitching. No redrawing or re-tracing required.

💎Texture & Depth

Techniques like puff embroidery, 3D stitching, and satin fills add dimension and visual richness to any garment.

4.What Makes 2026 Computerized Embroidery Trends Special

Computerized embroidery work in 2026 is not just another year for embroidery — it is a turning point. The industry is seeing a collision of old-world Indian craftsmanship with cutting-edge digital design, and the results are genuinely exciting. Here is what is trending right now and why it matters for your next embroidered piece.

✦Metallic & Zari Accents

Gold and silver metallic threads are making a strong comeback — not just on bridal wear, but on kurtas, caps, and even streetwear. Zari embroidery done via computerized machines delivers that regal shimmer with machine-level consistency.

◆Bold Geometric Patterns

Clean lines, sharp angles, and high-contrast geometric motifs are dominating collars, cuffs, and full-front designs. Computerized embroidery is the only method precise enough to execute these cleanly at any scale.

◈3D Textured & Puff Work

Designs that raise off the fabric — using foam-backed puff stitching or layered techniques — are trending fast. They add a tactile, dimensional quality that flat embroidery simply cannot replicate.

🍃Eco & Sustainable Threads

Organic cotton threads, biodegradable rayon, and naturally dyed fibers are entering the mainstream. Computerized machines work seamlessly with these eco-conscious materials — no quality trade-off.

What makes 2026 particularly unique is the role of AI-assisted design. Designers are now using algorithms to analyze trend data and generate embroidery patterns that feel both culturally rooted and commercially relevant. For the Indian fashion market — where ethnic wear demand is growing at a steady pace — this means faster turnaround, more personalized options, and designs that genuinely reflect what consumers want right now.

5.Personalized and Custom Embroidery

One of the biggest reasons people turn to computerized embroidery work in 2026 is the ability to get something uniquely theirs — not a mass-produced pattern pulled off a rack, but a design that carries their initials, their brand, their family crest, or a motif they saw and fell in love with.

What Can Be Customized?

Almost everything. You can personalize the design itself — from scratch or by modifying an existing template. You can choose your thread colors, including metallic Zari options in gold, silver, antique gold, or rose gold. You can select the fabric type — silk, cotton, georgette, velvet, or net — and specify exactly where on the garment the embroidery should appear.

Popular Custom Embroidery Use Cases

Bridal Lehengas

Wedding Sherwanis

Corporate Uniforms

Festive Kurtas

Personalized Gifts

Event Wear

Designer Dupattas

Luxury Caps & Bags

How Zari Zaika Creates Flawless Designs

Zari Zaika’s custom embroidery process starts with a one-on-one design consultation — understanding not just what you want, but why. Our in-house digitizers then convert your concept into a stitch-perfect file, which is previewed digitally before any fabric is touched. This means zero surprises, zero wasted material, and a finished piece that matches your vision exactly.

Custom computerised embroidery services have become significantly more accessible in recent years. What once required a minimum order of hundreds of units can now be done for a single garment — without a dramatic price penalty. That is the real game-changer for individual customers who want quality without compromise.

6.How to Choose Your Perfect Embroidery Style

Choosing the right embroidery style for your garment is not just an aesthetic decision — it is a practical one. The wrong stitch type on the wrong fabric will either look flat, feel uncomfortable, or wear out faster than expected. Here is how to match your needs to the right technique.

Match Your Fabric First

Lightweight fabrics like cotton, georgette, and net work best with flat stitch fills, satin stitches, and delicate running-stitch outlines. Heavy fabrics like velvet, silk dupatta, and bridal base cloth can handle denser, richer techniques — including Zari metallic work, puff embroidery, and layered satin fills.

Match Your Occasion Next

Popular Computerized Embroidery work Styles Explained

Zari Embroidery — Uses fine gold or silver metallic threads wound around a silk or polyester core. It produces a luminous, regal finish that is the hallmark of Indian bridal and festive wear. Computerized machines can now replicate traditional Zari patterns with remarkable accuracy.

Satin Stitch — Parallel stitches laid side by side to create smooth, solid-colored filled areas. Ideal for logos, lettering, and clean geometric shapes.

Puff Embroidery — A layer of foam is placed under the fabric before stitching. When the foam is trimmed after embroidery, the stitched areas rise above the surface, creating a 3D raised effect.

Chenille Stitch — Produces a thick, velvety texture. Trending on streetwear, hats, and casual jackets in 2026.

Chain Stitch — Loops of thread form a continuous chain. It gives a softer, more organic look — great for floral and nature-inspired motifs on kurtas and dupattas.

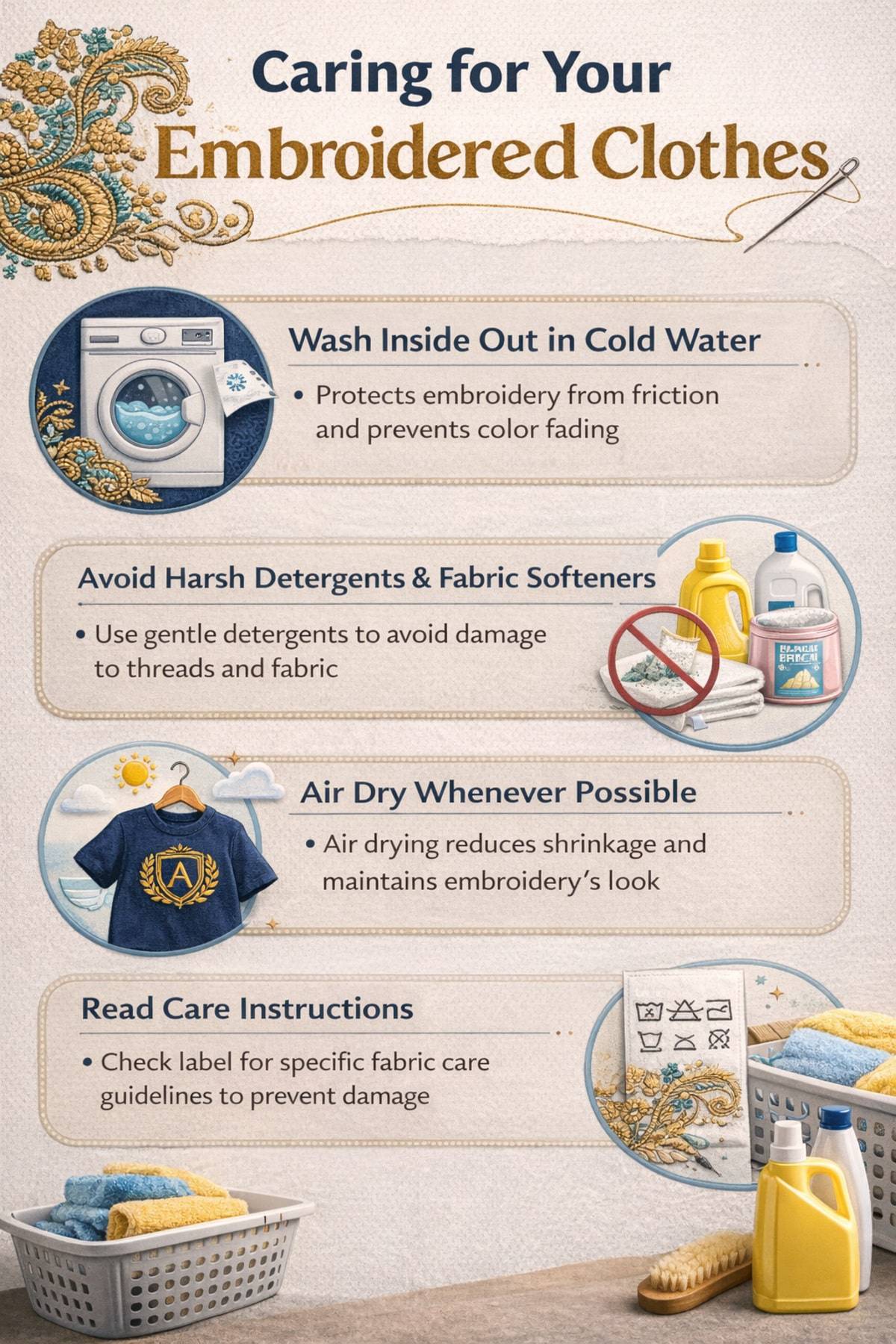

7.Caring for Your Embroidered Clothes

A beautifully embroidered garment is an investment — whether it cost you ₹500 or ₹50,000. The way you care for it directly determines how long it stays stunning. Here are the rules that actually matter.

For Zari & Metallic Embroidery

Metallic threads react with moisture and air over time, which can cause them to tarnish or lose their shine. Always store Zari-embroidered garments wrapped in soft muslin or cotton cloth — never plastic, which traps humidity. Dry clean only. If you must wash, use a gentle, lukewarm cycle inside out with a mesh laundry bag, and avoid any fabric softener or bleach.

For Standard Thread Embroidery

Turn the garment inside out before washing. Use cold water and a mild detergent. Avoid the dryer — heat can shrink threads and distort stitch patterns. For garments with dense embroidery, consider professional cleaning after every 3–4 wears to preserve stitch integrity.

General Storage Rules

Hang embroidered garments on padded hangers whenever possible. Folding puts pressure on stitched areas, which can cause the thread to loosen or the fabric to crease permanently around dense embroidery zones. For bridal or heavily embellished pieces, store flat in an acid-free tissue-lined box.

8.The Future of Computerized Embroidery work in Indian Fashion

India’s embroidery market is on a clear growth trajectory. The India Embroidery Market is expected to grow at a CAGR of 8.2% during 2025–2031, driven by rising demand for customized ethnic garments and the rapid adoption of computerized embroidery machines across manufacturing hubs like Surat, Mumbai, and Tirupur.

What does this mean for you as a consumer or a small business owner? More options, better quality at lower price points, and faster turnaround. The gap between “luxury bridal embroidery” and “everyday affordable embroidery” is closing rapidly.

Technology Is Changing the Game

AI-powered digitizing tools are now capable of converting rough sketches or even photographs into stitch-ready files — a process that once took a skilled digitizer several hours can now be done in minutes. This is making truly personalized computerized embroidery accessible to anyone, not just fashion houses with large budgets.

Sustainability Is No Longer Optional

The shift toward organic fabrics, recycled polyester, and water-saving machine embroidery is already reshaping the embroidery market. Eco-conscious threads and sustainable base fabrics are becoming standard offerings — and computerized machines are uniquely suited to minimize waste, since every stitch is pre-planned digitally.

India’s Cultural Heritage Meets Modern Technology

Traditional styles like Zari, Zardozi, Chikankari, and Phulkari are not disappearing — they are being digitized, scaled, and made available to a global audience through e-commerce. Computerized embroidery is the bridge that connects centuries-old Indian craft traditions with 21st-century manufacturing capability.

9.Hand Embroidery vs Computerized Embroidery

This is one of the most common questions from people exploring embroidery options for the first time. Both methods produce stunning results — but they serve very different needs. Here is a clear, honest comparison.

| Factor | Hand Embroidery | Computerized Embroidery |

|---|---|---|

| Speed | Slow — days to months per piece | Fast — hours for complex designs |

| Precision | Depends on artisan skill | Machine-perfect every time |

| Consistency | Slight variations between pieces | Identical across any batch size |

| Cost (single piece) | Higher for intricate work | Generally more affordable |

| Cost (bulk) | Very expensive at scale | Cost-effective for 10+ units |

| Design Complexity | Limited by artisan endurance | No practical complexity limit |

| Customization | Fully custom by nature | Fully custom via digital design |

| Cultural & Heritage Value | High — handmade authenticity | High when replicating traditional motifs |

| Best For | One-off heirloom pieces, Zardozi bridal work | Custom orders, branded wear, trending designs, bulk production |

Many designers and customers are now combining both methods — using computerized embroidery work for the base design and hand-finishing for select details like bead work or sequin placement. This hybrid approach delivers the best of both worlds: speed and precision from the machine, soul and texture from the artisan’s hand.

See the difference between hand embroidery and computerized embroidery

10.Common Challenges and How to Overcome Them

Computerized embroidery work is powerful — but like any craft, it comes with challenges. Knowing them upfront means you can avoid them entirely when you place your order.

1. Poor Digitization Quality

The Problem: A badly digitized file will produce stitches that bunch up, pull the fabric, or simply look blurry and unclean — no matter how good the machine is.

The Solution: Always work with an experienced digitizer or a service that offers a digital preview before stitching begins. At Zari Zaika, every design is digitized in-house and reviewed before production starts.

2. Wrong Fabric Choice

The Problem: Dense embroidery on a thin fabric will cause puckering, warping, or even tearing. Conversely, delicate stitch patterns on heavy fabric can look washed out.

The Solution: Match your embroidery density to your fabric weight. Ask your embroidery service for fabric recommendations based on your design — a good provider will flag this before you commit.

3. Color Mismatch

The Problem: Thread colors on screen look different than they do stitched on fabric, especially under different lighting or on different fabric colors.

The Solution: Request a color-matched sample or swatch before full production. For Zari and metallic threads in particular, always approve the thread spool against your actual fabric.

4. Sizing and Placement Errors

The Problem: The design ends up too large, too small, or off-center on the garment.

The Solution: Provide clear placement instructions with measurements. A professional service will confirm dimensions and positioning with you before hooping begins.

5. Thread Durability Over Time

The Problem: Low-quality threads fade, pill, or unravel after a few washes.

The Solution: Insist on industry-standard thread brands. Metallic Zari threads should be from reputable manufacturers to ensure they hold their lustre. Follow the care guidelines in Section 7 of this guide.

Conclusion

Computerized Embroidery Work — Your Gateway to Stunning, Custom Designs

Computerized embroidery work is no longer a behind-the-scenes industrial process — it is a creative tool that puts professional-grade embroidery directly in your hands. Whether you want a single personalized kurta with a Zari border, a bulk order of branded jackets, or a bridal lehenga with a design that is entirely your own, the technology is there, the quality is proven, and the options have never been wider.

In 2026, the Indian embroidery market is moving fast — toward sustainability, toward AI-assisted design, toward more accessibility. And at the center of it all is computerized embroidery: precise, versatile, and endlessly customizable.

If you are ready to move from idea to finished garment — or if you simply want to understand what is possible — Zari Zaika is here to make it happen. From the first design consultation to the last quality check, we handle every step with the care your garment deserves.